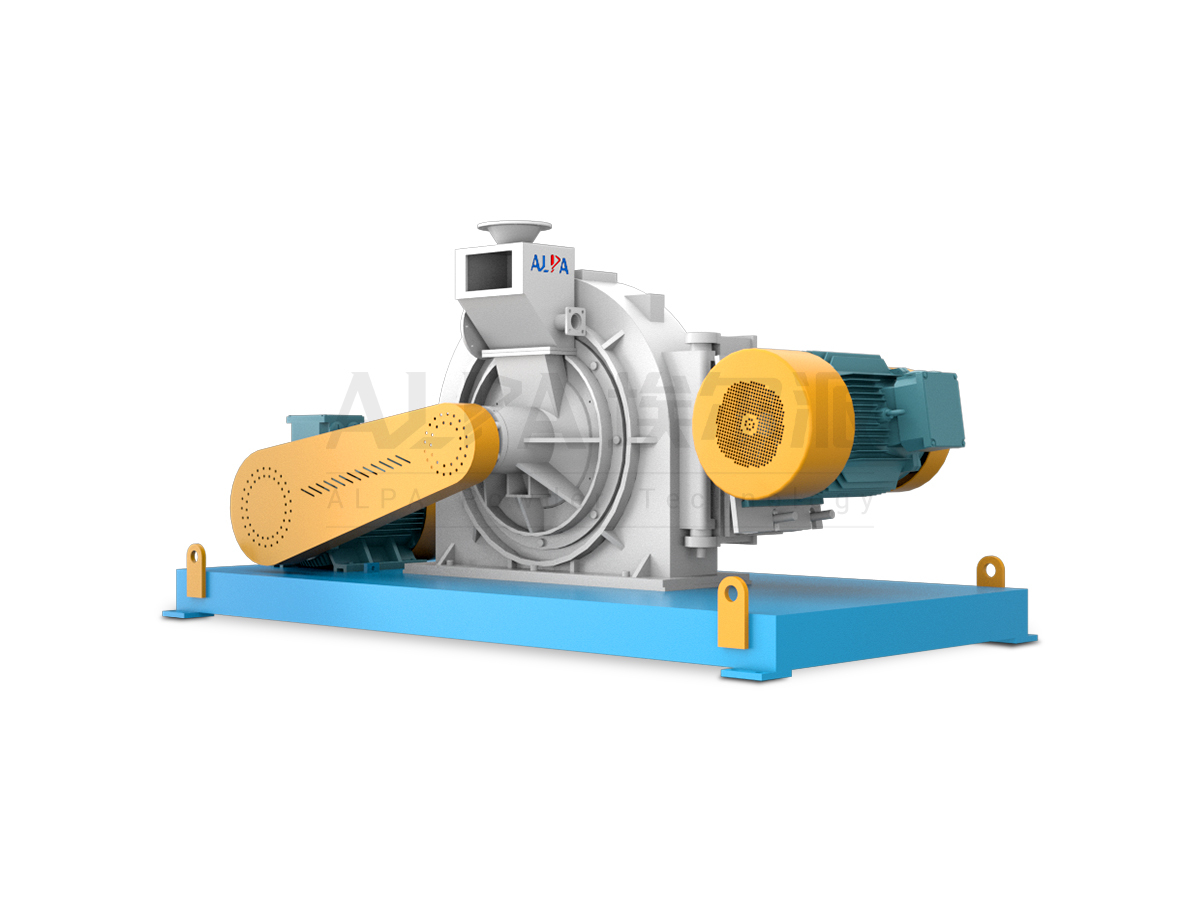

Horizontal Air Classifier(Single Classifying Wheel)

ALPA powder recommends that you learn more about FW/HTS Horizontal Air Classifier and learn more about the advantages, parameters, quotations and pictures of FW/HTS Horizontal Air Classifier.

Product Size:

Application area:

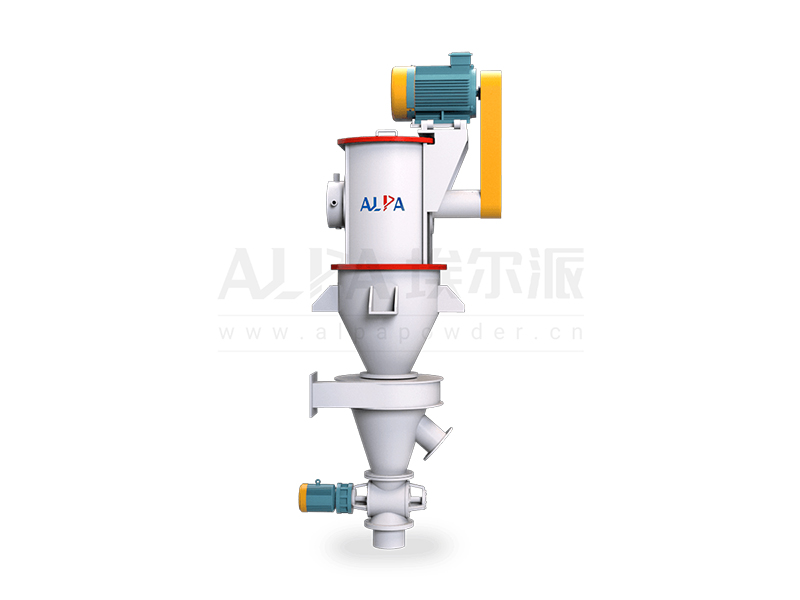

Air classifier works with cyclone separator, bag filter and suction fan to form a complete classifying system. Material would go from the bottom part of air classifier up to the classifying cham- ber by the air flow from suction fan. The classifier wheel with high-speed rotation would create a strong centrifugal force to separate coarse and fine powder. Qualified fine powder would go through the wheel vane then into the cyclone or bag filter, while coarse entraining fine powder would lose its speed and fall down along the wall of chamber to the inlet of secondary air. The secondary air flow would disperse it further and separates coarse and fine powder. Fine powder would go up to the classi- fying chamber for further classifying, while coarse powder would fall down and will be dischanged from the bottom outlet.

-

Performance characteristics

- Available D50:1.5-25μm.

- Suitable for precise classifying of dry micron material,, can classify spherical, flaky, needle-like particles, and can also classify particles of different densities.

- The linear velocity of horizontally installed classifying wheels is up to 80m/s.

- Classifying efficiency (extraction ratio) can be 60%~90%.

- Speed of wheel is equipped with velocity sensor and can be controlled by inverter, particle size can be adjusted freely.

- Horizontal classifier wheel with high speed and accurate vertex cutting.

- System negative pressure operation, meet environmental requirements, noise <76dB(A).

- The classifying wheel can be made of ceramic materials such as alumina, zirconia and silicon carbide, without metal pollution, meeting the requirements of high-purity materials.

- Grinding is completed in closed system, little dust, low noise in a clean and environmentally friendly process.

- PLC control system, easy operation.

- In conjunction with ball mill, table roller mill and Raymond mill to form closed circulation.

- The motor can be connected with a belt, which is stable and reliable, realizes high speed and increases the speed, and breaks through the problem that the well-known motor brand does not have a high-speed motor.

- Optional explosion-proof design, can also be upgraded to a nitrogen circulation system to meet the processing needs of flammable and explosive oxide materials.

Working principle

Technical parameter

Single Rotor

| Parameters/specifications | FW200 | FW280 | FW400 | FW520 | FW630 | FW800 |

| Production Capacity(kg/h) | 10~100 | 20~200 | 50~500 | 100~1500 | 200~2500 | 400~4000 |

| Product Size(d97:μm) | 3~45 | 3~45 | 3~45 | 3~45 | 3~45 | 5~45 |

| Classifying efficiency(%) | 60~80 | 60~80 | 60~80 | 60~80 | 60~80 | 60~80 |

| Installed Power(kW) | 7~11 | 15~19 | 21~28 | 23~30 | 52~60 | 67~77 |

Note: The production capacity is closely related to the particle size, specific gravity, hardness, moisture and other indicators of the raw materials. The above is only for selection reference.