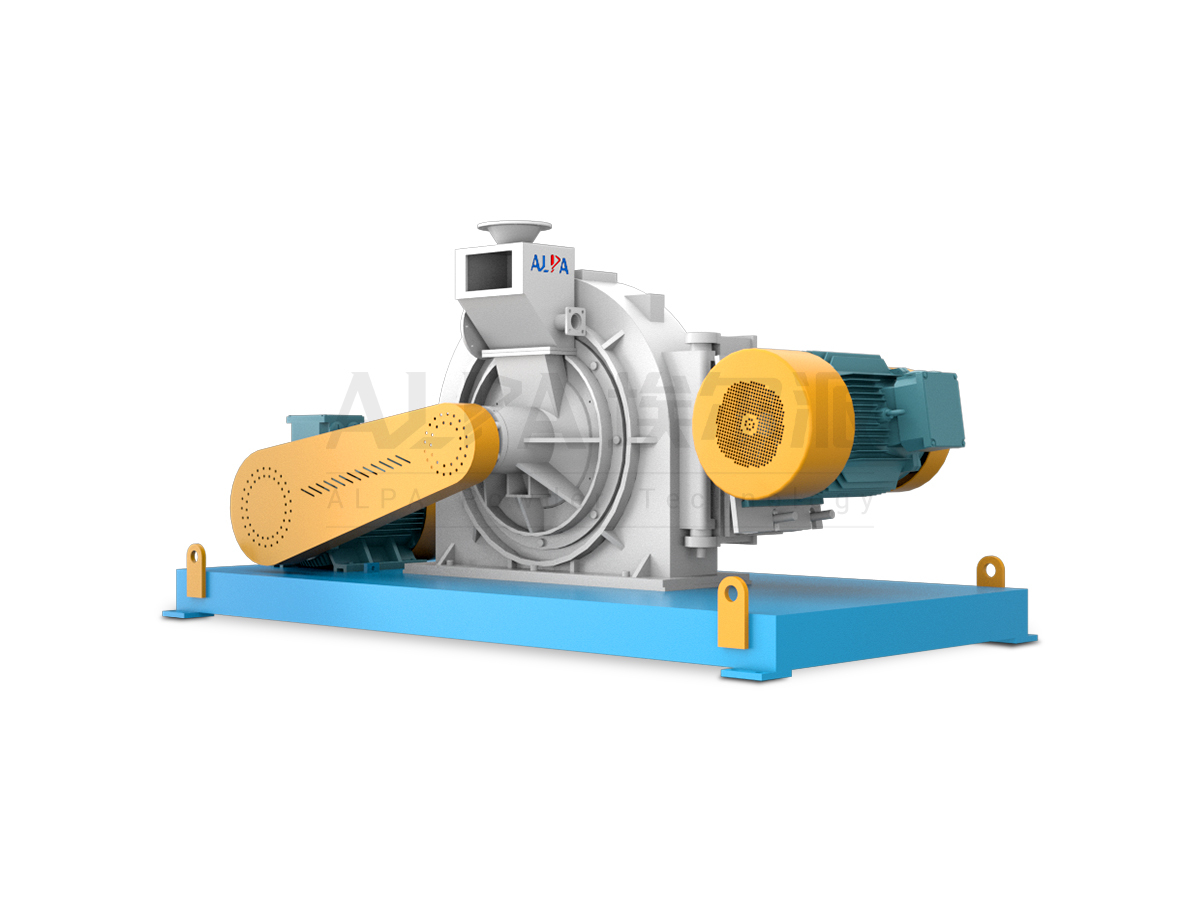

MZ Vibration Mill

The grinding medium (rod, segment and ball) in the grinding cylinder makes a strong ejection movement under the high-frequency vibration of the high-speed vibration exciter (or vibration motor)

Product Size:D50:2.5~150μm

Application area:Chemical industry, minerals, building materials, metallurgy, abrasives, ceramics, refractories, food, health products, new materials, etc.

The grinding medium (rod, segment and ball) in the grinding cylinder makes a strong ejection movement under the high-frequency vibration of the high-speed vibration exciter (or vibration motor),

The high-speed rotation movement and slow revolution movement cause strong impact, friction and shear on the scattered materials, so as to make the materials ultra-fine grinding and uniform mixing.

-

Performance characteristics

- Available D50:2.5~150μm

- Suitable for grinding raw materials with Moh’s hardness below 9.

- Compared with ball mill, higher grinding efficiency, small occupation.

- Particle size can be adjustable by adjusting parameters such as grinding medium, amplitude, and frequency. The finer powder can be given in conjunction with classifier in series.

- Grinding media and liners can be made of special materials such as high manganese steel, high chromium steel, stainless steel, alumina, zirconia, quartz, etc., which are wear resistant and less pollution.

- Air spring or rubber spring, instead of hard spring, long service life, good damping effect and low noise.

- Compact structure and small occupation.easy to disassemble and clean

- Lower installation power, wide application, high cost-performance.

- PLC control system, easy operation.

- Suitable for powder mixing, surface coating,mechanical chemical modification, etc.

- For heat sensitive and low melting materials, it can be crushed by water cooling or strong cooling.

- Finer powder can be given if to be used with classifier.

- Explosion-proof design can be selected to meet the requirements of ultra-fine grinding processing of flammable and explosive oxide materials.

Working principle

Technical parameter

Medium and small Amplitude Vibration Mill Technical Parameter

| Parameter | MZ10 | MZ30 | MZ50 | MZ100 | MZ200 | MZ300 | MZ500 |

| Chamber Volume(L) | 10 | 30 | 50 | 100 | 200 | 300 | 500 |

| Input Particle Size (mm) | 5 | 5 | 5 | 10 | 10 | 10 | 10 |

| Produce Size (μm) | 10-150 | 10-150 | 10-150 | 10-150 | 10-150 | 10-150 | 10-150 |

| Production Capacity (kg/h) | 1-5 | 5-20 | 10-50 | 20-150 | 50-300 | 100-500 | 150-800 |

| Power (kW) | 0.75 | 1.5 | 2.2 | 3.7 | 7.5 | 11 | 15 |

Big Amplitude Vibration Mill Technical Parameter

| Parameter | MZ100 | MZ300 | MZ500 | MZ600 | MZ800 | MZ1000 | MZ1200 | MZ2000 |

| Chamber Volume(L) | 100 | 300 | 500 | 600 | 800 | 1000 | 1200 | 2000 |

| Input Particle Size (mm) | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| Produce Size (μm) | 10-150 | 10-150 | 10-150 | 10-150 | 10-150 | 10-150 | 10-150 | 10-150 |

| Production Capacity (kg/h) | 100-200 | 200-300 | 300-600 | 400-800 | 500-1000 | 800-1500 | 1000-1800 | 2000-3000 |

| Power (KW) | 15 | 45 | 55 | 75 | 90 | 110 | 150 | 220 |