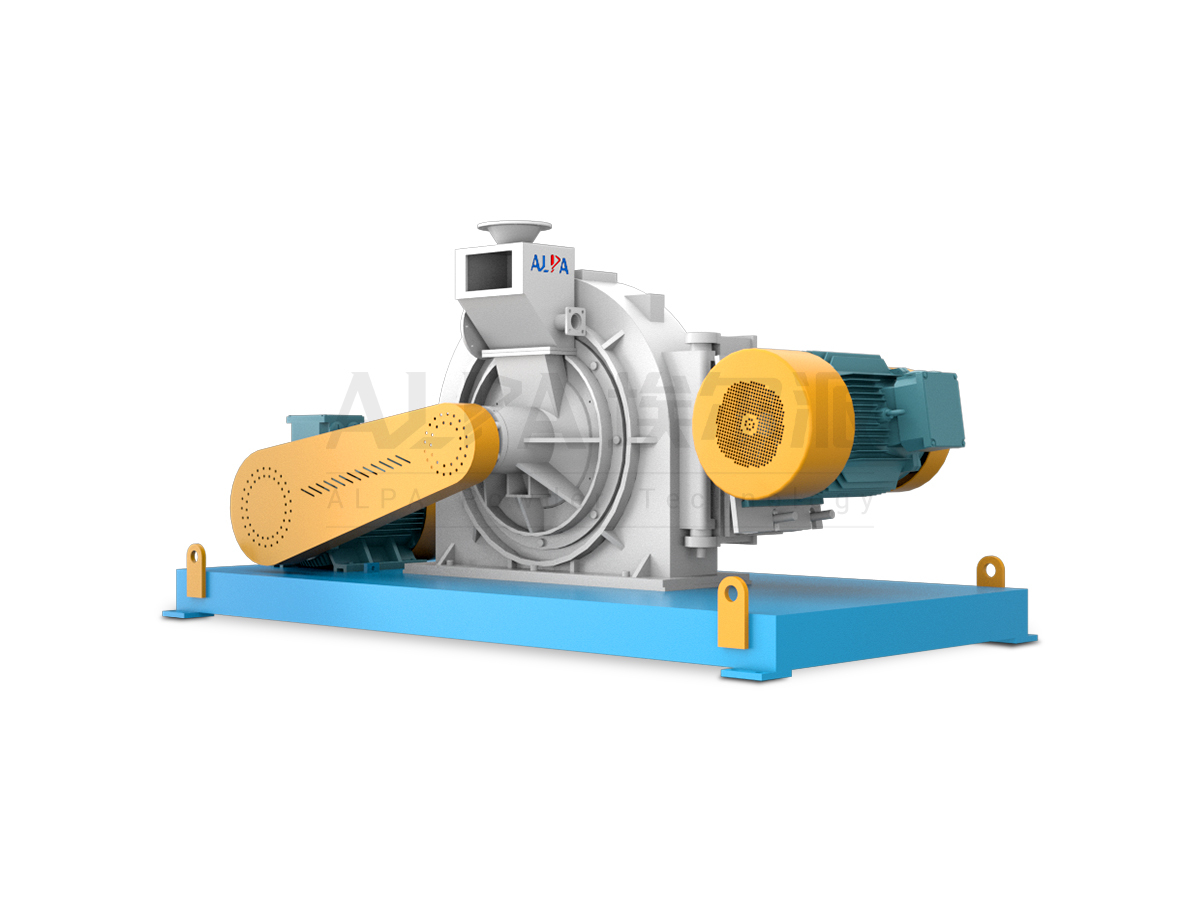

Rotor Mill for drying, dispersing and modifying

Drying and dispersing modified rotor mill is a very efficient mechanical mill, which is equipped with multiple rotors on its vertical shaft. The multi-layer crushing cutter head has strong shear force and dispersing force. It can be connected with the hot air source for multiple purposes, and realize the functions of drying and dispersing at the same time.

Product Size:D50:1~250μm

Application area:Dispersion and reduction of agglomerated materials, such as ultramicro crushing of light calcium, kaolin, aluminum hydroxide, magnesium oxide, polyvinyl alcohol, PVC, PE, cellulose and other heat sensitive materials. It is widely used in non-metallic mini

Drying and dispersing modified rotor mill is a very efficient mechanical mill, which is equipped with multiple rotors on its vertical shaft. The multi-layer crushing cutter head has strong shear force and dispersing force. It can be connected with the hot air source for multiple purposes, and realize the functions of drying and dispersing at the same time.

-

Performance characteristics

- Available D50:1~250μm.

- Integration of grinding and drying, high efficiency, low cost operation.

- Operation temperature up to 400℃, insulation design to bearing.

- Grinding head and lining are replaceable and can be selected based on different raw materials.

- The grinding chamber is welded by mild steel or stainless steel.

- Rugged seismic base.

- Special flange connection.

- The bearing assembly has an air purge design to prevent dust from entering.

- Relubricable bearing assembly design.

- Chain safety device.

- Compact structure and small occupation. easy to disassemble and clean.

- Lower installation power, wide application, high cost-performance.

- Grinding is in closed system, low dust and noise, clean and environmentally friendly production process.

- PLC control system, easy operation.

- Optional wear protection parts.

- Externally heated air, Achieve drying and dispersing functions at the same time. The grinding and dispersing area is under the action of the high-speed rotor, the material is in full contact with the hot air, fully heat exchange, moisture is taken away effectively, the heat source is more efficiently utilized. Energy saving 30%-50% compared with traditional drying processing.

- Built-in classifying wheel, oversize particle could be ground in circulation.

- Can be used in series with multi-stage classifiers to produce products with multiple sizes at one time.

- Explosion-proof design can be selected to meet the requirements of ultra-fine grinding processing of flammable and explosive oxide materials.

Working principle

Technical parameter

| 参数型号 | 350 | 500 | 750 | 1000 | 1250 | 1500 | 2000 |

|---|---|---|---|---|---|---|---|

| Rotate Speed rpm | 5580 | 4130 | 2760 | 2070 | 1650 | 1400 | 1050 |

| Linear velocity m/s | 102.3 | 108.1 | 108.3 | 108.3 | 108.3 | 110.0 | 110.0 |

| Power kW | 30 | 55 | 90 | 110~132 | 160~200 | 250~315 | 315~355 |

| Maximal Air Volume m³/h | 4000 | 6000 | 12000 | 15000 | 20000 | 25000 | 35000 |

| Minimal Air Volumem³/h | 1250 | 2000 | 3000 | 4000 | 5000 | 6000 | 8000 |

Note: The production capacity is closely related to the particle size, specific gravity, hardness, moisture and other indicators of the raw materials. The above is only for selection reference.