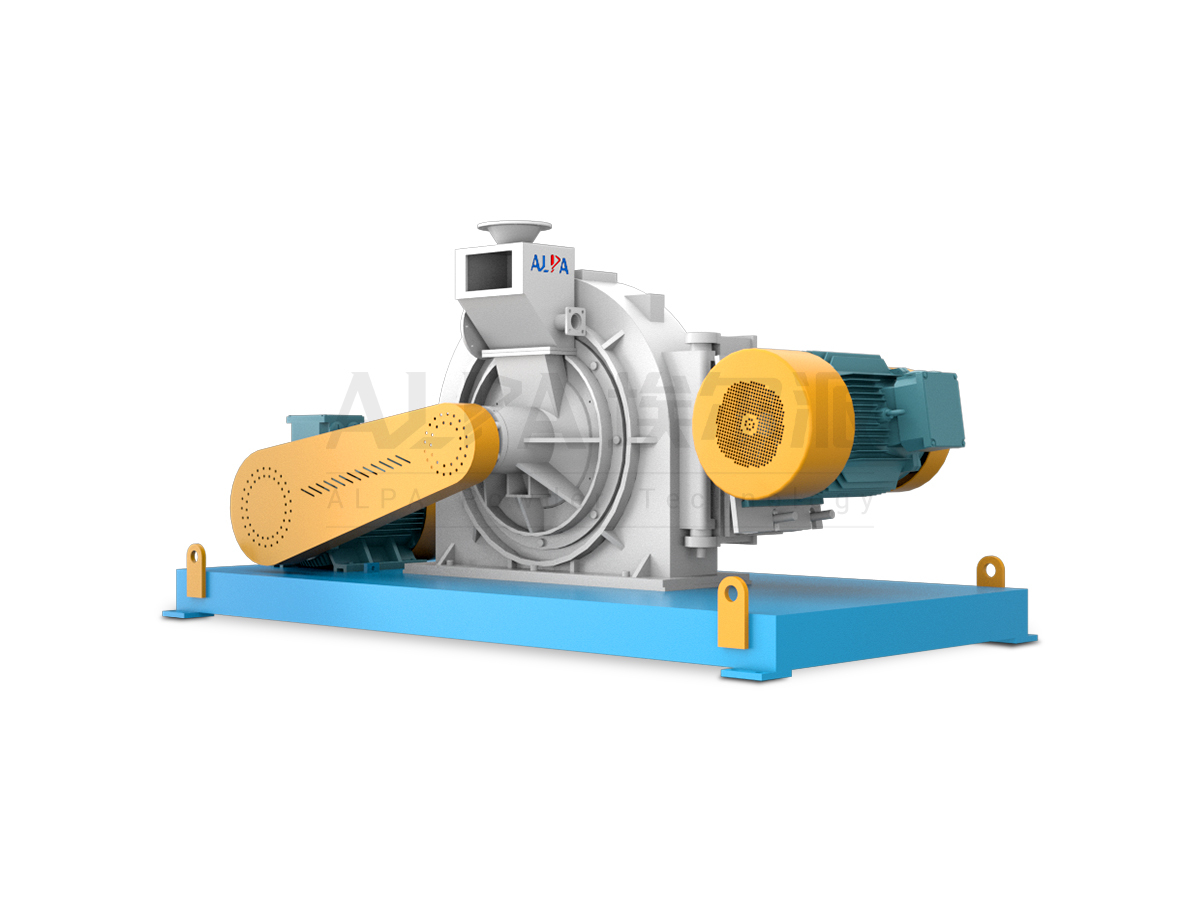

CUM-F Hammer Mill

The hammer installed on the rotor will rotate at high speed inside the hammer mill to break and grind the materials. The grinding particle size of the material is controlled by adjusting the rotating speed of the hammer and the size of the screen aperture.

Product Size:D50:10~850μm

Application area:Chemical industry, inorganic salt, medicine, food, pigment, dye, pesticide, battery material, mineral, refractory and other industries.

The hammer installed on the rotor will rotate at high speed inside the hammer mill to break and grind the materials. The grinding particle size of the material is controlled by adjusting the rotating speed of the hammer and the size of the screen aperture.

-

Performance characteristics

- Available D50:10~850μm.

- Sieve hole size 0.2mm-3mm.

- Compact structure and small occupation, easy to disassemble and clean.

- Lower installation power, wide application, high cost-performance.

- Different installation combinations, applicable to different process requirements.

- Grinding is in closed system, low dust and noise, clean and environmentally friendly production process.

- PLC control system, easy operation.

- The motor can be connected with a belt to increase the speed and break through the problem of high-speed motors without the well-known motor brand.

- Optional explosion-proof design, meet the ultra-fine grinding processing requirements of flammable and explosive oxide materials.

- High-temperature, low-temperature, normal-temperature, airtight cycle, Inert gas cycle designs are available, for different grinding requirements of different materials.

Working principle

Technical parameter

| Parameters/specifications | 160 | 250 | 360 | 500 | 630 | 800 | |

| Turbo Type F | Grinding Disc(mm) | 150 | 250 | 350 | 500 | 600 | 720 |

| Max. Rotation Speed(r/min) | 12000 | 7500 | 5550 | 3850 | 3200 | 2800 | |

| Power(kW) | 3~4 | 5.5~7.5 | 11~15 | 18.5~30 | 30~45 | 37~75 | |

| Product Size(mesh) | 20~325 | ||||||

| Production Capacity(kg/h) | 5~50 | 15~200 | 25~500 | 30~1200 | 50~1800 | 60~2000 | |

| Pin Type P | Grinding Disc(mm) | 160 | 260 | 360 | 520 | 630 | 730 |

| Max. Rotation Speed(r/min) | 12000 | 7500 | 5550 | 3850 | 3200 | 2800 | |

| Power(kW) | 4 | 7.5 | 15~22 | 37 | 45~55 | 55~75 | |

| Product Size(mesh) | 20~325 | ||||||

| Production Capacity(kg/h) | 20~200 | 35~1000 | 50~2000 | 75~3000 | 100~5000 | 200~10000 | |