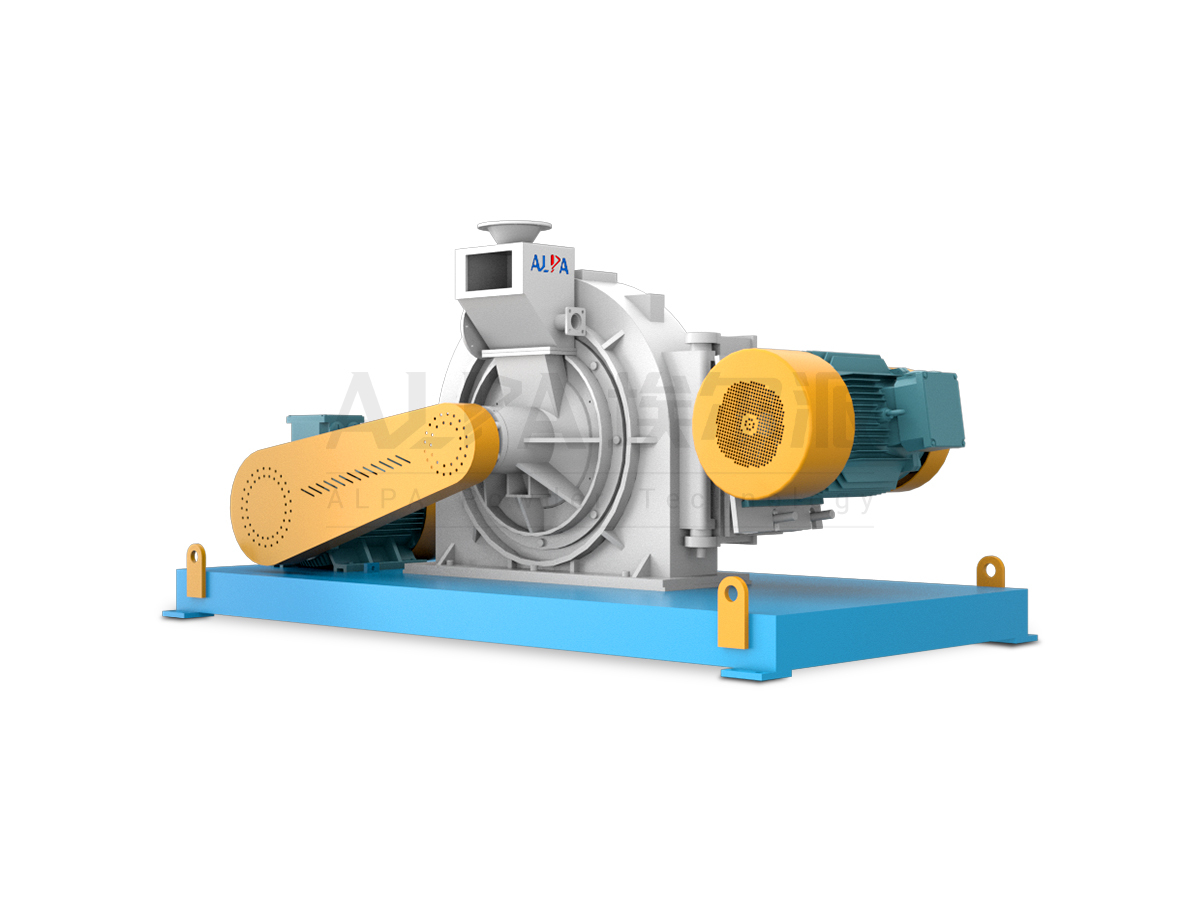

CUM-L Wood Fiber Mill

German technology, high-precision mechanical crusher and continuous technological innovation and upgrading are adopted, which is suitable for 80 mesh - 300 mesh (180um-50um). Wide crushing range, fine crushing particle size, high crushing output, no screen classification, negative pressure operation, in line with GMP requirements. It is widely used in Chinese herbal medicine, wood flour, wheat straw, corn straw, rice straw, sorghum straw, millet straw, sesame straw, peanut shell and other industries.

Product Size:

Application area:

German technology, high-precision mechanical crusher and continuous technological innovation and upgrading are adopted, which is suitable for 80 mesh - 300 mesh (180um-50um).

Wide crushing range, fine crushing particle size, high crushing output, no screen classification, negative pressure operation, in line with GMP requirements.

It is widely used in Chinese herbal medicine, wood flour, wheat straw, corn straw, rice straw, sorghum straw, millet straw, sesame straw, peanut shell and other industries.

-

Performance characteristics

Performance advantage

Wide crushing range

It has a wide range of comminution and is suitable for the comminution of drugs with different properties.

Fine crushing particle size

The crushing particle size is fine, and the crushing fineness can reach 300 mesh.

PLC program control

PLC program control is adopted to realize hierarchical authority management, which can be stored. Effective early warning is adopted for vibration sensors to prevent accidents.

No screen classification, negative pressure operation

No screen classification, negative pressure operation, independent air inlet and exhaust system, in line with GMP requirements.

Working principle

1. The material (≤ 6mm) is sent to the crushing chamber under the action of suction negative pressure of the fan. The crushing chamber consists of three crushing areas:

The first crushing area: Pendulum - it can crush all kinds of hard materials, such as minerals, skins and animals;

The second crushing area: knife swing - it can crush all kinds of fiber materials, roots, whole grass, fruits, fungi, flowers and others;

The third crushing area: fixed knife - the particle size is controlled by adjusting the gap. The crushed materials are transported to the classification chamber by the impeller.

The centrifugal force field is generated under the action of the grading wheel. The qualified fine powder is moved to the center of the rotor, sucked away by the induced draft fan, and then collected by cyclone collector and other components; The coarser particles return to the crushing chamber and are crushed again by the crusher. The material recovery rate is above 99%.

2. The unit is designed according to the "GMP" standard of pharmaceutical enterprises and made of all stainless steel. There is no dust flying in the crushing process. It can be installed in the clean workshop.

3. The unit has the advantages of simple operation, high production efficiency and low production cost. It is widely used in pharmaceutical, food and other fields.

4. The unit can not only be used alone, but also form a closed-circuit circulation system with air flow classifier to obtain finer particles.